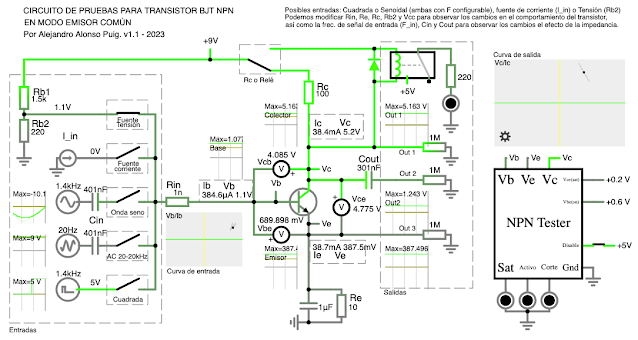

En este capítulo vamos a profundizar en uno de los clásicos de la electrónica analógica: El amplificador en emisor común con divisor de tensión.

Se trata de un uso del transistor NPN en su zona activa con el fin de amplificar una señal pequeña. Base de amplificadores diversos, como los de audio.

El divisor de tensión formado por Rb1 y Rb2 polariza la unión Base-Emisor con una tensión

VB = VCC . Rb2 / (Rb1+Rb2) = 1.15V

Para que la base siempre esté polarizada, hay que tener en cuenta que la señal de entrada (Vin) se sumará a la componente continua (del divisor de tensión). Esta ha de superar la tensión de polarización mínima de la Base, incluso en valores pico negativos de señal de entrada. Es decir que:

VB + Vin(min) > VBE(on) + VE

Donde:

- VBE(on) es la tensión base-emisor mínima para polarizar el transistor. Su valor está entorno a los 0.6-0.7V para transistores de silicio (los comunes)

- VBE (tensión Base-Emisor) la podemos aproximar a 0.7v. Aunque implicará un error de precisión, en la mayoría de los casos nos permitirá obtener valores bastante aproximados.

- VE (tensión de Emisor respecto de masa) es igual a VB - VBE = 1.15v - 0,7v = 0.45V

- IE (corriente de Emisor) por ley de ohm es igual a VE / Re = 0.45v / 10Ω = 45mA,

- IC (corriente de Colector) es igual IB + IE pero IB es muy baja (ver curva característica), por lo que se puede aproximar que IC ≈ IE = 45mA.

- VRc (tensión en Rc, o entre fuente (VCC) y Colector) es igual a Rc . IC = 4.5V

- VC (tensión de Colector respecto de masa) es igual a VCC - VRc = 4.5V

- VCE (tensión Colector-Emisor) es igual a VC - VE = 4.05V

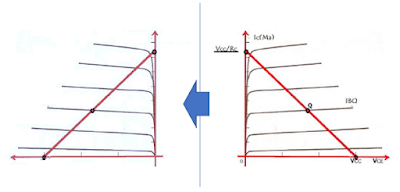

- Rc permite establecer (junto con VCC) la recta de carga estática, permitiendo calcular los puntos de corte y saturación. El punto Q de trabajo será la intersección de la recta de carga con el VCE calculado.

- Re aumenta la estabilidad del amplificador, pero ha de utilizarse en paralelo con un condensador (Ce)

- Ce es un condensador de desacoplo para atenuar componentes alternas y mejorar la estabilidad del amplificador

- Ci y Co son condensadores de acoplo que eliminan la componente continua. Para ello han de elegirse de manera que su reactancia sea baja para las frecuencias utilizadas en el amplificador.

La gráfica siguiente muestra como es la respuesta frecuencial de la reactancia (XC) de Ci y Co en este amplificador de ejemplo.

Se puede acceder a la simulación del amplificador en este enlace: ENLACE

Poniendo el amplificador en reposo (desactivando la fuente de señal pero dejando la fuente de tensión), obtenemos valores

- IB=384µA, superior a los 200µA para el punto Q calculado arriba,

- IC=38.5mA, algo inferior a los 45mA calculados previamente

- VCE=4.8V, algo superior a los 4.05V calculados previamente

- VBE=690mV, similar a los 0.7V considerados previamente

Pareciera que o bien la simulación, o bien los cálculos son incorrectos, pero debe tenerse en cuenta que el transistor elegido en la simulación es un modelo genérico que no funciona exáctamente como el BC547 utilizado, por lo que los datos obtenidos son diferentes, pero orientativos.

Análisis empírico

El paso siguiente es montar el circuito y medir los valores anteriores, con un BC547 real, con el fin de comprender mejor el comportamiento del transistor.

Una vez montado el circuito, con el uso de un polímetro obtenemos los siguientes datos en reposo:

IB=137µA, muy diferente de los 200µA para el punto Q calculado arriba,IC=38.5mA, algo inferior a los 45mA calculados previamente

VCE=3.9V, algo inferior a los 4.05V calculados previamente

VBE=690mV, similar a los 0.7V considerados previamente

Esta es una cuestión que nos lleva a algunas consideraciones importantes:

- Una simulación solo puede acercarse a la realidad si los modelos de los componentes se corresponden con los utilizados en la realidad. En nuestro caso el BC547. Al haber utilizado un modelo genérico, es natural esperar diferencias, aunque eso no quita valor a la simulación como acercamiento al comportamiento del sistema.

- Hemos asumido, por simplicidad, que VBE = 700mV en vez de 660mV del caso específico de este transistor. Para mejorar la precisión en este caso es recomendable inspeccionar el datasheet del componente para identificar mejor sus parámetros.

- También hemos asumido, por mantener sencillo el ejemplo, que el voltaje resultante del divisor de tensión se mantiene constante (VB = 1.15V), pero esto no es así, porque al tener la carga del transistor, se produce una pequeña caída de tensión. Como consecuencia el valor real es VB = 1.12V. Esta diferencia, aunque es de solo 30mV, junto con la del punto anterior, de 40mV son fundamentalmente las causantes de las diferencias entre el modelo teórico y el empírico, aunque también hay otros elementos que influyen, como la temperatura del componente.

Hasta ahora hemos podido visualizar datos concretos con el polímetro, pero el osciloscopio nos va a permitir:

- Ver y comparar las señales de entrada y salida, así como su distorsión

- Visualizar el punto Q y la recta de carga, así como las zonas de corte, saturación y activa.

Para la visualización de entradas y salidas, disponemos las sondas de un osciloscopio de doble canal del siguiente modo:

Lo que nos permite ver la amplificación en tensión de la salida (señal roja o amarilla) respecto de la entrada (azul) y su desplazamiento en fase.

Otra interesante visualización es la de la recta de carga y punto Q. Para ello utilizaremos un osciloscopio de doble canal, que permita modo XY y lo conectaremos según se muestra a continuación. Es importante asegurarse que la tierra del osciloscopio no coincide con la masa del circuito amplificador para que esta disposición funcione.

Finalmente podemos observar los efectos de la distorsión de la señal cuando entra en zona de corte y saturación.

Para ello no tenemos más que sustituir Rb2 por un potenciómetro y mover este para alterar la tensión sobre la base y por tanto su corriente IB, lo que desplaza la señal de salida por la recta de carga arriba y abajo. Esto es algo que observaremos tanto en el osciloscopio en modo XY como en el osciloscopio que nos muestra la señal de salida, ya que esta quedará distorsionada.

Concluímos así este análisis teorico-práctico del comportamiento del transistor bipolar en modo emisor común, para aplicaciones de amplificación.

Se muestra a continuación el vídeo explicativo completo.